A Complete Power Solution

An Unlikely, Yet Cost-Effective Solution To Sound Quality And Noise Issues

MusicCord combines the following benefits into a single component:

- More Power - for "bigger sound" with more body and authority, increased dynamics and volume, and more extended frequency range. MusicCord increases transient current flow.

- Integrated Power Conditioning - for improved clarity, richer tone and harmonics, and greater resolution. MusicCord filters phase distortions to alleviate grain, harsh transients and muddy bass. Soundstage imaging and spatial qualities are enhanced.

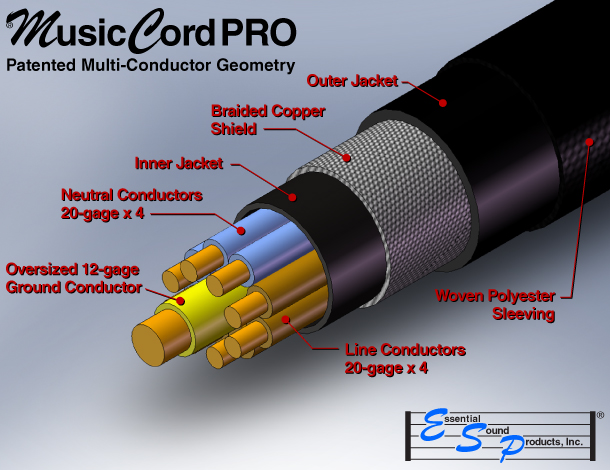

- Shielded Cable Construction - MusicCord's patented cable geometry with maximum-coverage braided copper shield rejects RFI, lowering noise.

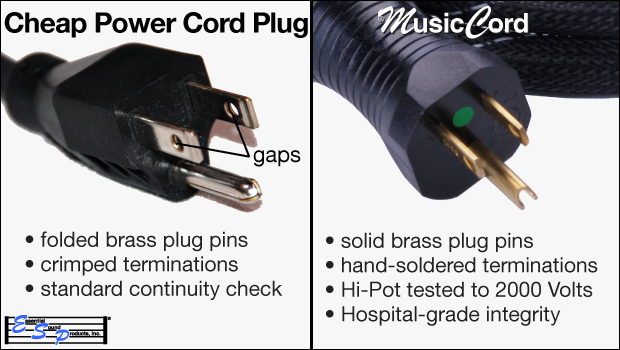

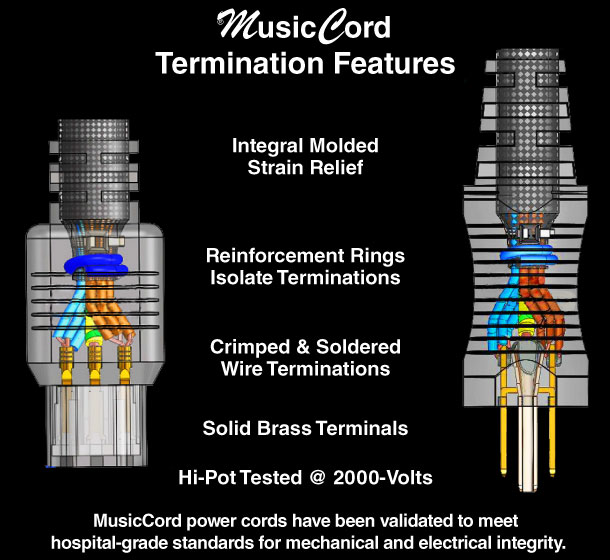

- "Road-Worthy" Build Quality - MusicCord's rugged reliability is inherent in the cable design and enhanced during the build process. With hand-soldered terminations, reinforcements that isolate the terminations from handling stresses and Hi-Pot testing to 2000-Volts, MusicCord established a new standard - "Audio Grade"TM

Read how stock power cords contribute to sound quality and noise isses you may be experiencing and how MusicCord provides a complete power solution for your audio system.

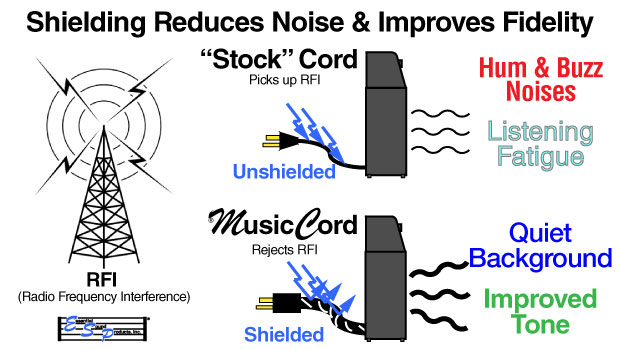

Why All Audio Power Cords Should Be Shielded

Unshielded Power Cords Pick-up RFI

- Hum In Guitar Amps Caused By Fluorescent Lighting Ballasts

- Increased Background Noise

- Can Sometimes Pick Up Radio Stations!

Unshielded Power Cords Radiate EMI

- Current Flow Creates Magnetic Field Around Power Cable

- Can Cause Hum Noises In Nearby Signal Cables

MusicCord's maximum-coverage braided copper shield & spiraled conductors reject RFI, contain EMI.

Improved Tone and Fidelity

Stock Power Cords, A Current "Bottle Neck"

Stock power cords cause sound quality issues including:

- Constrained Dynamics

- Lack Of Bass Extension

- Boomy, Muddy Bass Response

- Thin Tone, Lacking Full Harmonic Palette

- Harshness During Transients & Loud Passages

- Unintelligible Speech And Vocals

- Blurred Soundstage Imaging

- Ear Fatigue During Long Listening Sessions

These sound quality issues can usually be traced to the component power supply not getting enough current to operate properly. The 18-guage power cord supplied with most audio gear acts as a "bottle neck", restricting current flow. Switching to a 14-gauge power cord introduces more phase distortions, exacerbating conditions like sluggish bass response, blurred imaging and high-frequency roll-off. Neither power cord provides an optimal solution.

MusicCord’s patented cable geometry with integrated power conditioning dramatically improves transient current flow while filtering phase distortions to provide greater bass extension and tighter control, a richer tonal palette with harmonics intact, and elimination of midrange harshness during transients and loud passages. The midrange becomes smoother and more pleasing. Ear fatigue is eliminated.

Once midrange harshness is reduced, volume can be increased to make it easier to understand dialog and vocals. All these improvements are appreciated against a quiet background because of our shielded cable construction and attention to detail in the termination process.

More than any other audio cable manufacturer, Essential Sound Products has strived to back up our claims with audio samples and demonstrations, and test and measurement data, and to share this information with you, our customers. For more details, please visit our power cable technology web page.

Lower Noise

Hiss, Buzzes and Hum

Background noise in an audio system can be insidious and if loud enough crippling, making its use unfeasible. In the recording studio, a higher noise level means less usable dynamic range. Noise can be caused by numerous external factors as well as poorly built or damaged, unshielded power cords. Some of these causes include:

- Loose Conductor Terminations

- Short Circuit Due To Loose Strands

- Damaged Conductors

- Lack Of Proper Grounding Or Poor Grounding Connection

- Poor Contact Between Connector Pins And Power Inlet/Outlet Contacts

- Fluorescent Lighting Ballast

- Dimmer Switches

- Power Cords Near Signal Cables

It only takes a loose connection to have a buzz noise in your system. Cheap power cords are notorious for loose crimp joints. Their molded connector body provides minimal strain relief. Just a tug on the cable instead of grabbing the connector body to detach the power cord can loosen conductor terminations and cause a buzz noise. These cheap power cables typically have weak, easily deformed folded metal contacts that may not consistently make good contact with the mating power inlet or outlet. Gaps between folded metal allows contamination and moisture, which promote corrosion and reduce conductivity.

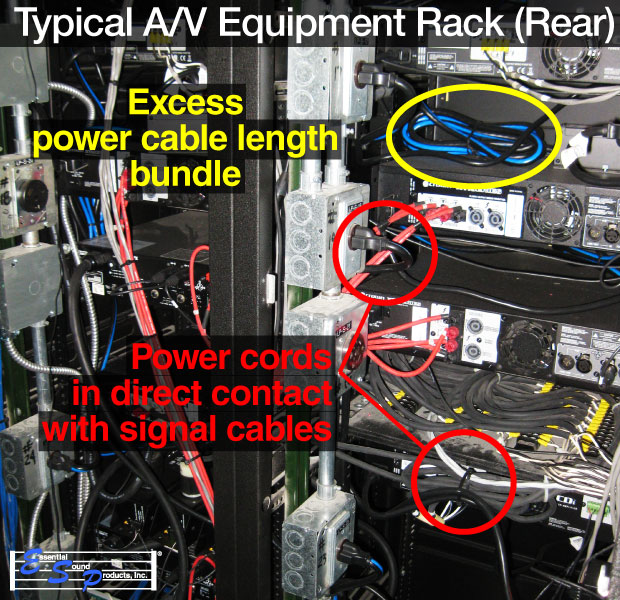

A/V Equipment Racks

Audio/Video equipment racks present a particular noise challenge. Power cords for each component are intermixed with interconnects, speaker cables and control wiring. Excess power cable length exacerbates the problem of signal cables coming in close proximity and sometime contacting the power cables. Practically all power cables supplied with audio/video gear are unshielded. Unshielded power cords in this environment presents a potential noise problem for two reasons.

Unsheilded Power Cables Pick Up RFI

Like unshielded signal cables, power cords are susceptible to RFI (Radio Frequency Interference). Numerous guitar and bass players have told us that when performing in venues with fluorescent lighting, they have experienced hum noise through the amplifier using their stock, unshielded power cord. Others have reported they have even picked up faint radio stations! These issues were eliminated when they switched to MusicCord!

Unsheilded Power Cables Radiate EMI

Unshielded power cords can actually cause hum noise in nearby signal cables. The strong magnetic field surrounds the power cable is a source of EMI (Electro-Magnetic Interference). A Mylar/foil shield found on some interconnects is ineffective at stopping magnetic field propagation. Best practice is to space signal cables away from power cords, but in most installations it is practically impossible to avoid some undesired routings.

More Than Just A Power Cord

MusicCord Features And Benefits

More Power, Better Tone & Lower Noise

MusicCord is much more than just a power cord. MusicCord combines the following benefits into a complete integrated solution:

- More Power - for "bigger sound" with more body, increased dynamics and volume, and extended frequency range

- Integrated Power Conditioning - for improved clarity, more natural rich tone, greater resolution and lower noise

- Rugged Reliability - "road-worthy" build quality for years of trouble-free service

MusicCord unleashes the full performance potential of your audio system! You’ll get “bigger sound” with increased dynamics and volume. And the bass will be more extended and tight! You’ll feel more like you just bought a new amplifier rather than replacing a power cord! The soundstage will expand in all directions with greater clarity and more resolution. Imaging is enhanced with more precise location of vocals and instruments. Your tone will be transformed from thin to "fat" with natural warmth and the full harmonic pallet now intact. The midrange will be smoother and fatigue free - more "analog" sounding digital!

Integrated Power Conditioning

Integrated power conditioning addresses a problem that cannot be solved by typical conditioners – eliminating the inferior power cord! Moreover, the circuit’s electrical properties can be better optimized to more effectively reduce phase distortions and improve transient current flow. Compare the overall sound quality improvement afforded by MusicCord to a traditional power conditioner.

Let your ears be the judge!

Patented Geometry With Shielding

How do we do it? MusicCord’s patented cable design features multiple line/neutral conductors spiraled around an oversized ground conductor and maximum-coverage braided copper shield.

Most types of audio/video signal cables are available with shielding. You may wonder why shielded power cords are not standard with audio gear. Aside from added cost, there is a legitimate sound quality issue associated with most shielded power cords. Shielded power cords will cause distortion in the bass frequencies. The sheild exacerbates the second harmonic of the ac mains carrier frequency, which is 60Hz in North America (50Hz in most countries with 220/240-Volt ac mains). Therefore, you'll have a bass "bump" at 120Hz.

MusicCord’s shield in is intentionally spaced away from the current-carrying conductors by an inner jacket to reduce potential interaction. This additional spacing combined with using multiple current carrying conductors where each has a weaker magnetic field than a single large conductor, dramatically reduces potential interaction. You get the benefits of the shield without the negative distortion effects.

Below is a photo from a recording studio where shielded MusicCords replace the unshielded OEM power cords. First, you notice the shorter power cables, which eliminate excess length and make for a professional appearance. More important, MusicCord’s patented shielded cable design is effective at rejecting RFI and preventing EMI in the Cat-5/6 interconnect cabling.

MusicCord's conductors are hand-terminated to plug and connector pins. Each conductor is crimped, then hand-soldered to insure optimal electrical conductivity and mechanical integrity. To make the terminations further resistant to handling stresses, reinforcement rings are assembled to the cable ends, then over-molded. If the cable is tugged, the stress is on the reinforcement, not the terminations! Each MusicCord is Hi-Pot tested at 2000-Volts to insure insulation integrity. That's 10-20 times greater than the ac mains voltage the power cord will experience in normal operation. This severe test will reveal any potential for short circuit.

Power cords are the most overlooked part of the audio system. Many customers believe they need to replace the component to solve sound quality and noise issues. In many cases, buying a new component will not solve the problem.

What is really needed is a power cable that has been designed and developed to address the unique requirements of audio/video gear in the environments they are used.

What you need is MusicCord.

Investing in a MusicCord power cord represents a small fraction of the cost of purchasing a new component.

Guaranteed Performance and Quality

Our Guarantee

After more than 25-years’ experience and much research and development, Essential Sound Products has accrued a wealth of understanding why the power cord has such a profound impact upon audio component performance and how to optimize the design to improve sound quality in several key areas. We're so confident that if you try our high performance ac power cords that you'll be completely satisfied, we back them with a 30-day satisfaction guarantee and lifetime warranty.

Click the icons below for more information.

What To Buy?

Each Model Uniquely Balances Performance & Price, For Your Application

- MusicCord Professional Series - Most affordable, with "road worthy" build quality. Delivers "bigger sound", increased dynamics and extended frequency range. A popular choice for instrument amplifiers, recording studio applications, PA and home audio/video systems. MusicCord-PRO affords even greater bass extension and control. Models:

- ESpecial Series - Additional pre- and post-processing steps result in "ES" models that deliver more refinement and resolution. Best "performance value" for high end recording and mastering studios, and high performance home audio/video systems. Models:

- Reference Series - The best parts, materials and processes to achieve the highest performance level, for the most discriminating audiophile High-End Audio applications. Models: